- HHD

- Wuhan Hubei

- In Stock

- In Stock

1. Min 98%

2. Bulk in stock

3. Analysis report offer

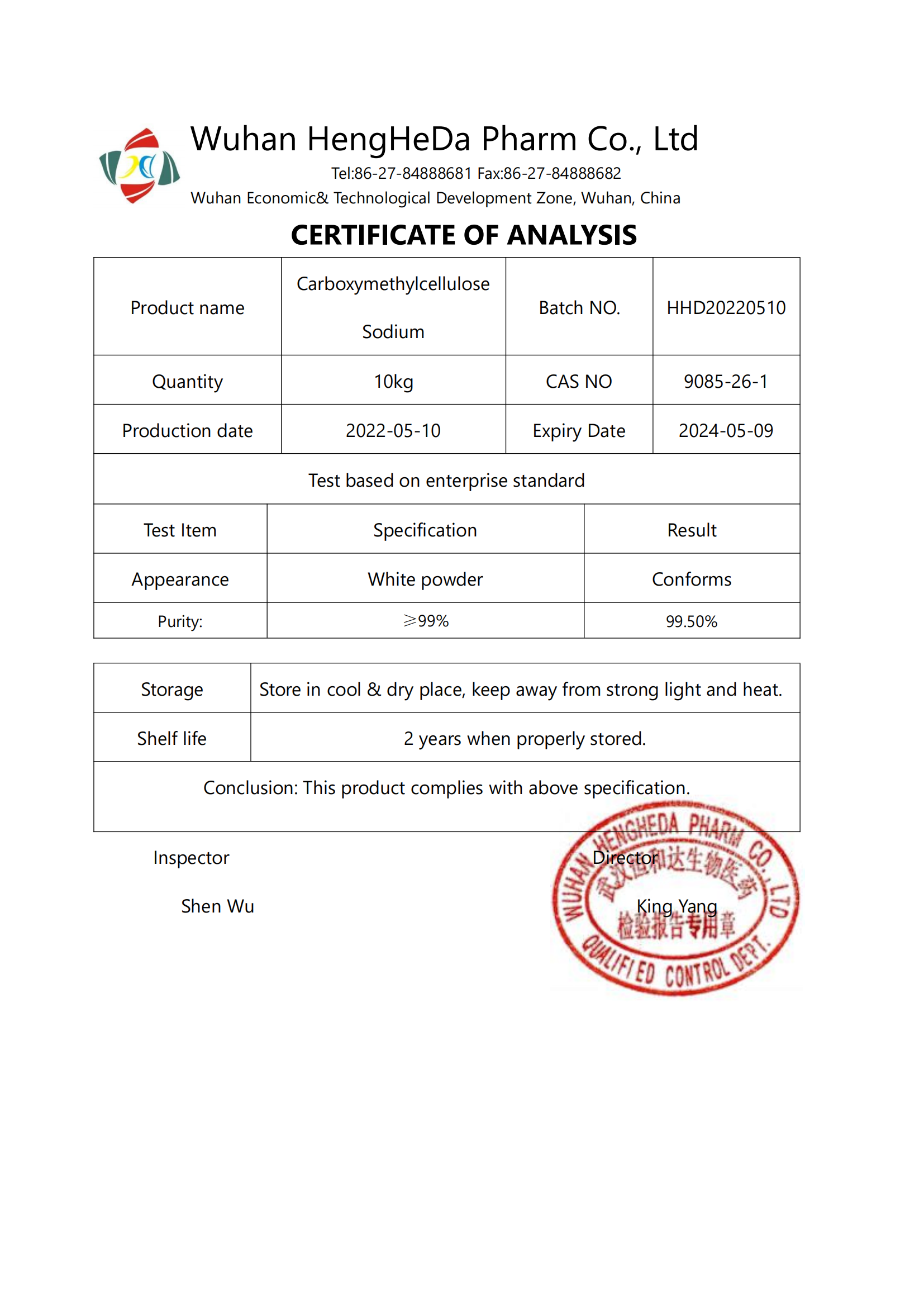

Product Name | CMC (sodium carboxymethyl cellulose |

Other Name | Carboxy Methyl Cellulose |

CAS No. | 9085-26-1 |

Appearance | White powder |

Purity | 98% |

MF | C8H16NaO8 |

Storage | Room temperature |

Shelf Life | 2 years |

Grade | Food Grade |

Carboxymethyl cellulose sodium (also known as sodium carboxymethyl cellulose, carboxymethyl cellulose, CMC, Carboxymethyl, Cellulose Sodium, Sodium salt of Caboxy Methyl Cellulose) is the most widely used and most used in the world today. The type of cellulose. The abbreviation CMC-Na is a cellulose derivative with a degree of glucose polymerization of 100-2000 and a relative molecular weight of 242.16. White fibrous or granular powder. Odorless, tasteless, odorless, hygroscopic, insoluble in organic solvents.

1. CMC for Oil Drilling: It can increase viscosity and reduce water loss in drilling fluid, cementing fluid and fracturing fluid. It also plays the role of protecting the wall of well, taking drilling trifles, protecting drilling bit, preventing mud loss and increasing drilling rate.

*Usage: add to mud directly or glue solution preparation.

*Addition: 0.1-0.3% in fresh water mud; 0.5-0.8% in salt water mud.

2. CMC Ceramic Grade: It's used for ceramic embryo, glazing pulp and colored glaze in ceramic industry.

*Addition:0.03%-0.2% used in ceramic embryo; 0.05-0.2% used in glazing pulp; 1.4-4.0% used in colored glaze.

3.CMC Paper Grade: It's used in making pulp so as to improve the retention rate and increase humidity and strength; when used in surface sizing, CMC can improve internal adhesion, decrease printing dust and enhance printing quality as molding reagent. In paper coating, CMC also helps the dispersion and fluidity of paint, improves appearance of paper and smoothness, upgrades optical performance and printing adaptability.

*Addition: 0.3-1.5%.

4. CMC Construction Grade: Used in construction to improve water retention and strength.

5. CMC for other industries: As coagulant, water retaining, thickener and binder, it's also used in paint, carpet gum, mosquito coil incense, tobacco, electric welding, textile, battery, printing and others.

Every batch of our product was tested by authorized independent third party, Analysis testing center, Shanghai branch, Chinese Academy of Science. We send goods to customers with test report and COA. Our products were also tested by American Analytical Chemistry Laboratories and Chromadex too....more